Stainless steel decorative profiles have gained popularity in recent years due to their versatility, durability, and aesthetic appeal. These profiles are used in various applications, ranging from interior design to architectural projects. In this comprehensive guide, we will explore everything you need to know about Stainless steel decorative profiles, including their types, benefits, applications, and much more.

Definition of Stainless Steel Decorative Profiles: Stainless steel decorative profiles are specialized metal profiles made from stainless steel, designed to enhance the aesthetic appeal of various structures and objects. These profiles come in various shapes and sizes, allowing for creative and functional applications in design and architecture.

Importance and Relevance in Modern Design: In today’s design landscape, the use of stainless steel decorative profiles has become essential due to their sleek appearance, robustness, and versatility. They are widely used in both residential and commercial projects, adding a modern and polished look to interiors and exteriors alike.

History and Evolution

Early Uses of Stainless Steel: Stainless steel has been in use since the early 20th century, primarily for its corrosion-resistant properties. Initially, it was used in industrial applications where durability was paramount.

Development of Decorative Profiles: The concept of using stainless steel for decorative purposes emerged later, as architects and designers recognized its potential for adding aesthetic value. Over time, advancements in manufacturing technologies have allowed for more intricate and varied designs.

Types of Stainless Steel Decorative Profiles

Angles: Angles are L-shaped profiles commonly used for edging and framing. They provide structural support while offering a clean finish.

Channels: Channels are U-shaped profiles used for various framing and support applications. They are often employed in shelving, countertops, and partitions.

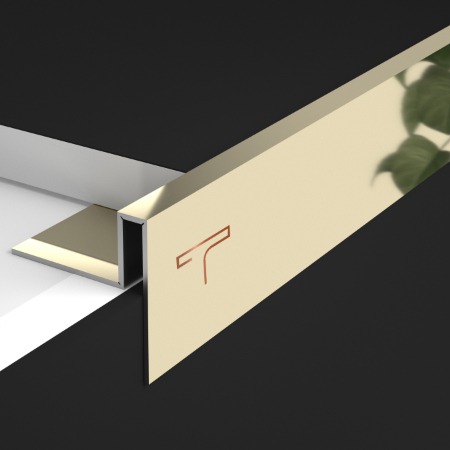

T-Profiles: T-profiles are used to create divisions in surfaces, such as in flooring or wall cladding. They offer both functional and decorative benefits.

U-Profiles: U-profiles are versatile and can be used for edging, framing, and creating clean separations between different materials.

Custom Profiles: Custom profiles are designed to meet specific design requirements. They offer unique solutions for complex projects.

Material Composition

Types of Stainless Steel Used: The most common types of stainless steel used in decorative profiles are 304 and 316. Type 304 is known for its excellent formability and weldability, while type 316 offers superior corrosion resistance, making it ideal for harsh environments.

Benefits of Each Type: Type 304 is preferred for interior applications due to its affordability and ease of fabrication. Type 316, with its higher resistance to chemicals and saltwater, is better suited for outdoor and marine applications.

Manufacturing Process

Cutting: The process begins with cutting the stainless steel sheets into the desired shapes and sizes. This can be done using laser cutting, water jet cutting, or traditional methods like sawing.

Bending: The cut pieces are then bent into the required profiles using specialized machinery. This step requires precision to ensure the correct angles and dimensions.

Finishing Techniques: The final step involves finishing the profiles to enhance their appearance. Common finishing techniques include polishing, brushing, and coating. These finishes not only improve the look but also add an extra layer of protection against corrosion.

Applications

Interior Design: SS decorative profile are extensively used in interior design for creating elegant trims, moldings, and accents. They are popular in modern and minimalist designs.

Exterior Architectural Elements: In exterior applications, these profiles are used for cladding, facades, and decorative trims. They add a contemporary touch to buildings while offering durability and resistance to the elements.

Furniture: Stainless steel profiles are also used in furniture design, providing sleek and durable edges and supports for tables, chairs, and cabinets.

Signage: In the signage industry, stainless steel profiles are used to create sturdy and attractive frames and letters.

Art Installations: Artists and sculptors use stainless steel profiles to create modern art installations that are both aesthetically pleasing and durable.

Benefits of Using Stainless Steel Decorative Profiles

Durability: Stainless steel is known for its strength and longevity. Profiles made from this material can withstand significant wear and tear, making them ideal for high-traffic areas.

Aesthetic Appeal: The sleek and polished look of stainless steel adds a touch of sophistication to any design. It complements a wide range of materials and styles.

Corrosion Resistance: One of the main advantages of stainless steel is its resistance to corrosion. This makes it suitable for both indoor and outdoor applications, even in harsh environments.

Low Maintenance: Stainless steel profiles are easy to clean and maintain. They do not require painting or sealing, reducing long-term maintenance costs.

Comparative Analysis

Stainless Steel vs. Aluminum: While both materials are lightweight and durable, stainless steel offers superior strength and corrosion resistance. Aluminum, on the other hand, is easier to work with and more cost-effective.

Stainless Steel vs. Brass: Brass has a distinct aesthetic appeal with its golden hue, but it is prone to tarnishing and requires regular maintenance. Stainless steel, although less flashy, offers better durability and lower maintenance.

Design Considerations

Choosing the Right Profile: When selecting a stainless steel decorative profile, consider the application, desired aesthetic, and environmental conditions. Profiles should be chosen based on their ability to complement the design and withstand the conditions they will be exposed to.

Compatibility with Other Materials: Stainless steel profiles should be compatible with other materials used in the project. For instance, combining stainless steel with wood or glass can create striking contrasts and enhance the overall design.

Installation Guide

Tools and Materials Needed: Installing stainless steel decorative profiles typically requires basic tools such as a measuring tape, level, saw, and drill. Specific adhesives or fasteners may also be needed depending on the application.

Step-by-Step Installation Process:

- Measure and mark the installation area.

- Cut the profiles to the required length.

- Secure the profiles in place using appropriate fasteners or adhesives.

- Ensure all profiles are aligned and level.

- Clean the profiles to remove any installation debris.

Maintenance Tips

Cleaning Techniques: Regular cleaning with mild soap and water is usually sufficient to keep stainless steel profiles looking new. For stubborn stains, specialized stainless steel cleaners can be used.

Preventing Corrosion: Although stainless steel is resistant to corrosion, exposure to harsh chemicals or saltwater can cause damage over time. Regular cleaning and protective coatings can help prevent corrosion.

Repairing Damaged Profiles: Minor scratches and dents can be polished out. For more significant damage, replacing the affected section of the profile may be necessary.

Case Studies

Successful Projects Using Stainless Steel Decorative Profiles:

- Modern Office Building: Stainless steel profiles were used extensively in the cladding and interior trims, adding a sleek and professional look.

- Luxury Residential Apartment: Custom stainless steel profiles were used to create unique furniture pieces and decorative accents.

- Art Gallery: Stainless steel frames and trims were used to enhance the visual appeal of the gallery space, providing a contemporary backdrop for the artwork.

Expert Insights

Quotes from Architects and Designers:

- “Stainless steel decorative profiles offer an unmatched combination of durability and aesthetic appeal. They are my go-to choice for modern projects.” – Jane Doe, Architect

- “The versatility of stainless steel allows for endless design possibilities. It’s a material that can truly elevate any space.” – John Smith, Interior Designer

Common Challenges

Addressing Installation Issues: Common issues include misalignment and improper fastening. These can be addressed by careful measurement and using the right tools and techniques.

Overcoming Design Limitations: Sometimes, the standard profiles may not meet specific design needs. In such cases, custom profiles can be fabricated to achieve the desired look.

Latest Innovations

New Finishing Techniques: Advances in finishing techniques have led to the development of new textures and colors for stainless steel profiles. These innovations allow for greater customization and design flexibility.

Eco-Friendly Manufacturing Processes: The stainless steel industry is increasingly adopting sustainable practices, such as using recycled materials and reducing energy consumption during production.

Future Trends

Emerging Designs and Applications: The future of stainless steel decorative profiles looks promising, with new designs and applications emerging regularly. From advanced architectural elements to innovative furniture designs, the possibilities are endless.

Predictions for the Industry: As sustainability becomes more important, we can expect to see more eco-friendly practices and materials being used in the production of stainless steel profiles. Additionally, technological advancements will continue to enhance the quality and versatility of these profiles.

Summary of Key Points: Stainless steel decorative profiles offer a perfect blend of durability, versatility, and aesthetic appeal. They are suitable for a wide range of applications, from interior design to architectural projects. With proper selection, installation, and maintenance, these profiles can significantly enhance the look and functionality of any space.

Final Thoughts and Recommendations: Whether you’re a designer, architect, or homeowner, incorporating stainless steel decorative profiles into your projects can provide lasting beauty and performance. Consider exploring custom options to achieve unique and tailored designs.